Gradient Scale - Finalist FEIDAD 2005

Gradient Scale was conceived and built for "AustirArchitecture" Exhibition and was

Finalist at the Far Eastern International Digital Architecture Design Award 2005

Project by SPAN Architects

Production Strategy & Milling Path Design by Manfred Hermann

text from iaacblog

Synopsis

The main aim of the gradient scale project was to experiment and to scrutinize the concept of scale in architecture. In general the concept of scale is considered to be a very rigid idea, following rules that seem to be unbendable. To understand plans or models, architects and contractors are bounded to a formula, or etiquette of communication, the scale. The gradient scale project background is a thesis, which formulates the idea of non-sequential scalar growth. The entire project is an experimental digital scape, produced as a presentation platform for the projects of SPAN (Matias del Campo & Sandra Manninger) at the AustriArchitecture exhibition in the Zumtobel Lightforum in Vienna, Austria.

To achieve the conceptual idea of a continuously growing scalar model an MEL algorithm was developed which repeated a series of 5 curves along the predefined length of the exhibition object. These curves were connected in Maya, creating a Birail 3plus surface. By creating several iterations of forces influencing the surface, different degrees of articulations of the final element were created which leaded to the resulting object. The entire object can be seen as an experimental playground for scaleless architecture. The consequence being a deformation field for projects. Take for example the idea of placing a long project on the gradient scale.

Production

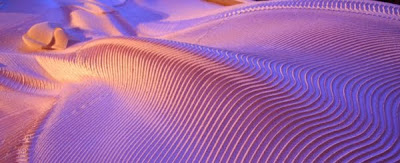

The main theoretical background, and the digital fabrication means applied in this project are interlocked with each other. Certain Issues connected to digital production methods were explored using a 3axis-milling machine. The Software Surfcam, which is used to calculate the NC files for the milling machine gives the architect a powerful tool to examine different surface patterns which emerge from the isoparms created in the MAYA model. By consciously manipulating the isoparms direction the final, milled result can be severely formed, as well as by choosing different mill bits and variating the stepsizes of the milling path. There is a wide range of possible applications in architecture for pattering. The jagging and rippling of the surface can be used to create reinforcement ribs in the panel’s structure, the objects surface can get a defined direction.

Jagging can be used as a basis for geometrically consistent apertures. The rippling can help to reduce the noice in interiors, or can be used to control the acoustical properties of a concert hall. There are many more of possible applications. Another issue explored in the production of the gradient scale is the problem of panelization. The Object is 5.4m long and 1.2m wide. It had to be produced in 3 Segments. Like in a real construction situation, it had to be considered how the piece is divided into sections, which are put together on site. The MAYA model, and its isoparms, provide a possible approach to the problems solution. Instead of cutting the piece in straight rectangular pieces, the cuts follow the models isoparms, creating puzzlelike joints. As the joints follow the MAYA models geometry, their formal appearance matches the entire projects language.